7 Tips for Printing on Sweatshirts

Screen printing on sweatshirts tends to be more difficult than printing on t-shirts. Printing on both sweatshirts and sweatpants provides different screen printing techniques.

Tip #1:

More adhesive than usual to hold the garment in place is necessary. Failure to have enough will cause the garment to lift. The sweatshirt can be misprinted if you are not careful.

Tip #2:

You need to apply new adhesive after three sweatshirts.

Tip #3:

Raise the off-contract of your screens higher than you would for printing on a t-shirt.

Tip #4:

The next tip is to cool down the garment when printing multiple colors on the sweatshirt.

How? To do this, use a chiller plate or cool-down station before printing other colors.

Tip #5:

If you have a pocket or pouch on the front of the sweatshirt, raise the off-contract accordingly. Don’t forget to make adjustments throughout the process of printing if necessary.

Tip #6:

Place the sweatshirts carefully through the dryer. This step is necessary to avoid the sweatshirt coming in contact with the heating element inside the dryer chamber.

Tip #7:

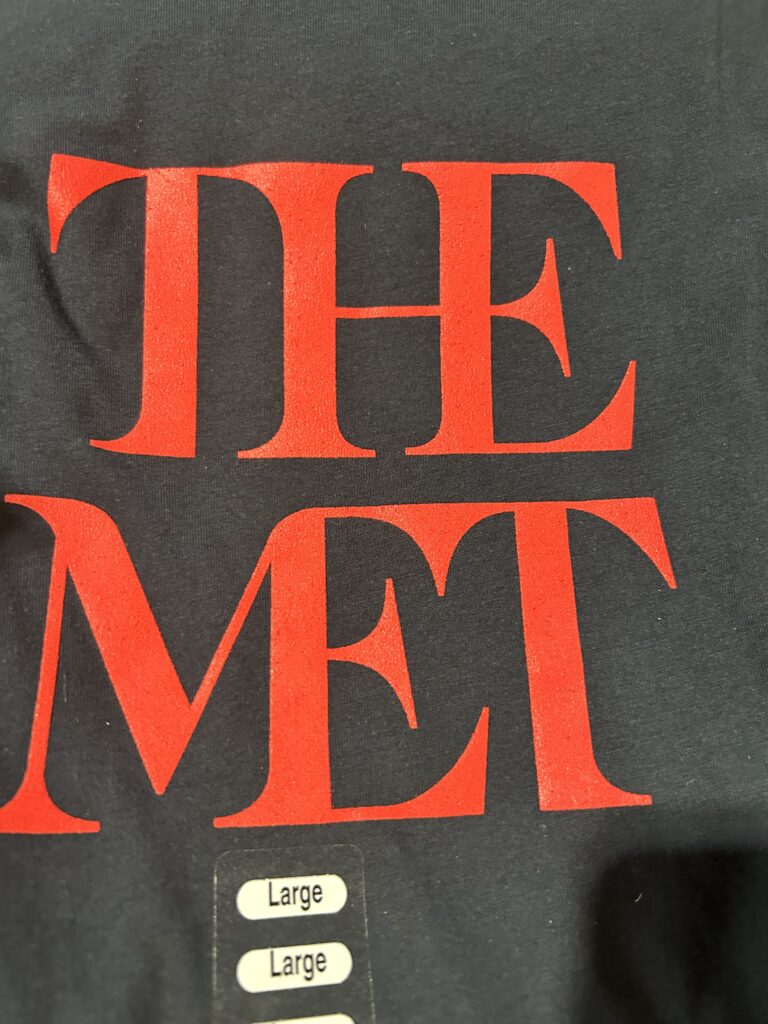

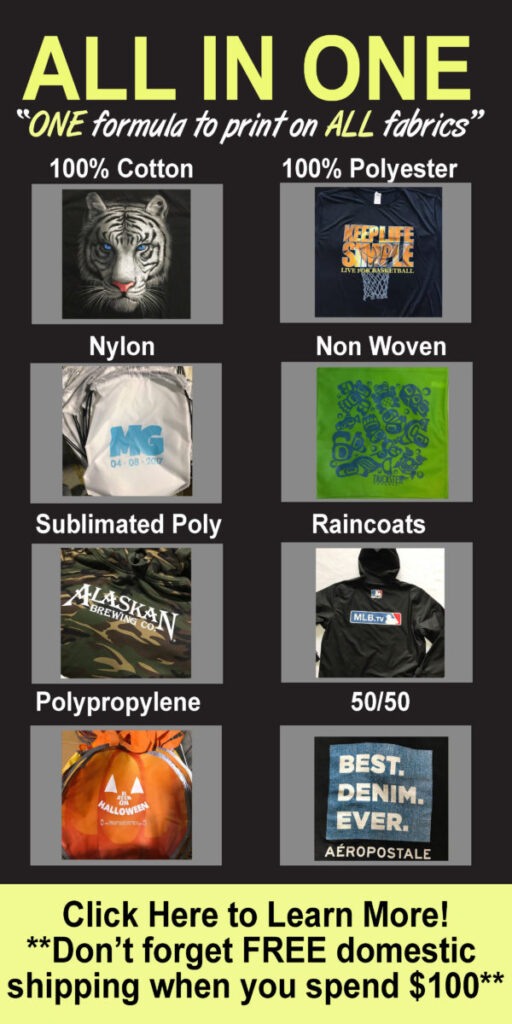

Use low-cure ink for printing on sweatshirts. The ink will adhere to thicker fabrics like sweatshirts, raincoats, and sweatpants.

1. The ink is biodegradable

2. Excellent opacity and coverage

3. No catalyst needed

4. Works on all fabrics

5. Cure with a flash or at 260 degrees F

6. Covers fibers on cotton

7. Prevents heat sensitive fabrics from shrinking

8. Blocks dye migration on polyester and sublimated polyester

9. Prevents scorching

10. Prevents crawling

11. Works great on nylon, cotton, 50/50, non woven, polypropylene, polyester, and raincoats.

-

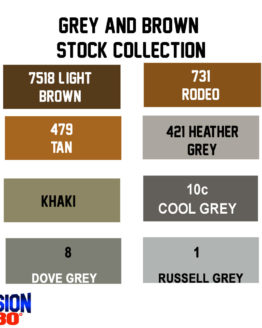

Grey and Brown Stock Collection$29.95 – $459.95

Grey and Brown Stock Collection$29.95 – $459.95 -

Purple and Pink Stock Color Collection$29.95 – $459.95

Purple and Pink Stock Color Collection$29.95 – $459.95 -

Blue Fusion 180 Stock Color Collection$29.95 – $459.95

Blue Fusion 180 Stock Color Collection$29.95 – $459.95 -

Green Fusion 180 Stock Color Collection$29.95 – $459.95

Green Fusion 180 Stock Color Collection$29.95 – $459.95 -

Yellow Fusion 180 Stock Color Collection$29.95 – $459.50

Yellow Fusion 180 Stock Color Collection$29.95 – $459.50 -

Orange Fusion 180 Ink Stock Color Collection$29.95 – $459.95

Orange Fusion 180 Ink Stock Color Collection$29.95 – $459.95 -

Red Fusion 180°Ink Stock Collection$29.95 – $459.95

Red Fusion 180°Ink Stock Collection$29.95 – $459.95 -

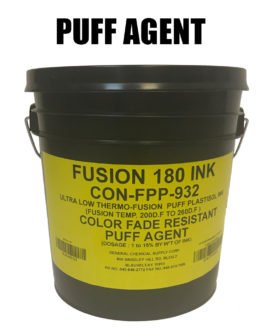

Low Cure Puff Agent$44.00 – $149.00

Low Cure Puff Agent$44.00 – $149.00 -

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

- 5 Videos Mixing Ink

- The 10 Best Prints this Fall with Low Temp Ink

- Print of the Day and SUMMER Savings!

- Top 10 Screen Prints of 2023

- Top 10 Products to Add to Your Screen Print Shop

- 5 Tips to Make Your Screen Print Shop Stand Out

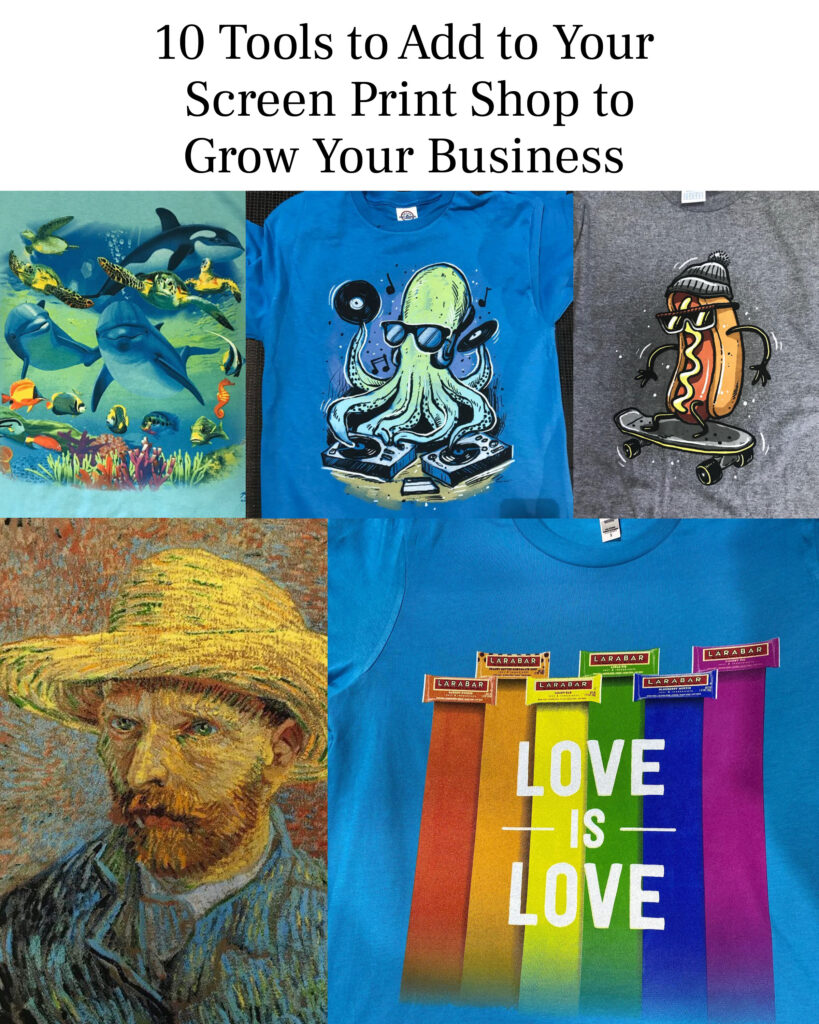

- 10 Tools to Add to Your Screen Print Shop To Grow Your Business

- 8 TIPS FOR CREATING QUALITY ARTWORK AND PRINTING WITH LOW CURE INK

- 8 Fabrics Low Cure Ink Adheres to

- 5 Videos Curing Fusion 180 with a Flash

- How to Mix Custom Colors with Our Matching System

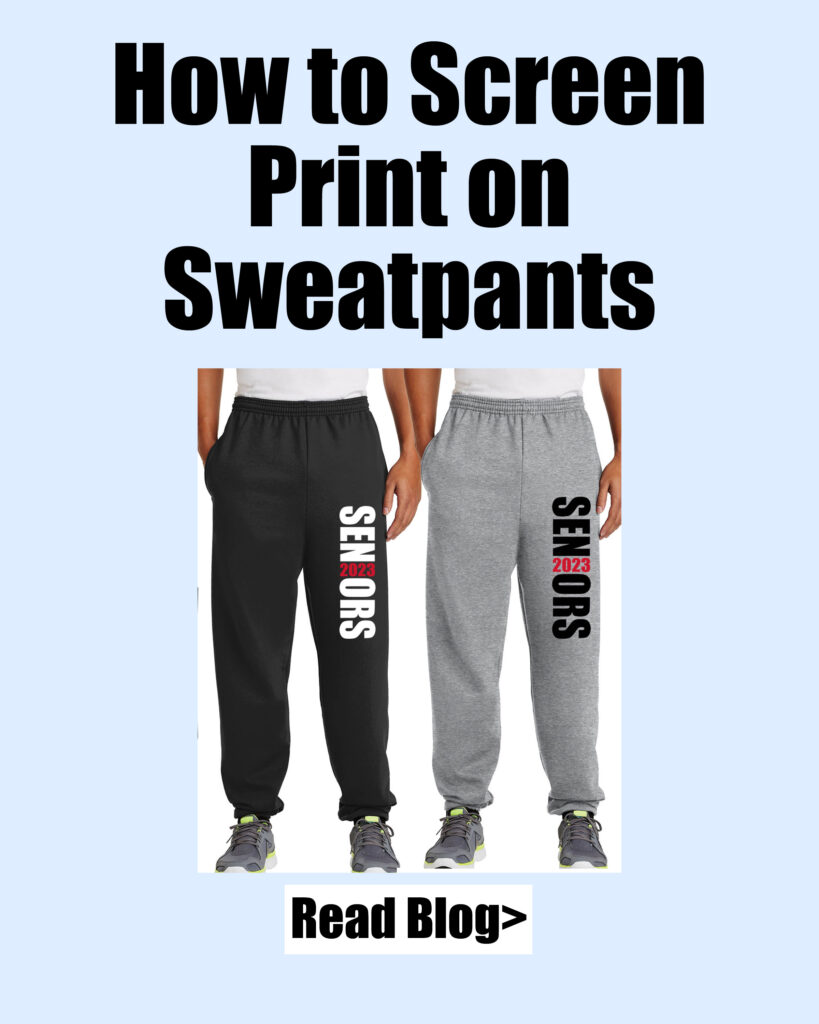

- How to Screen Print on Sweatpants