Fusion 180° is the ink of the future. Our dream was to create a extreme low temperature ink that will change screen printing for everyone in the industry and that is exactly what we accomplished with dedication and determination. Do you run into problems when printing on heat sensitive materials? Do you want to save money by not having to replace garments damaged by high heat or dye-migration? Look no further… Fusion 180° was created to solve all of these issues. All you have to do is lower the temperature of your dryer.

Why use low cure biodegradable white ink?

Fusion 180 ink adds miraculous Bio Base to the entire ink system. Bio Base makes the ink biodegradable and soft, improving viscosity. Fusion 180 ink with Bio Base remains low cure stays soft longer and flows beautifully through fine meshes without sacrificing coverage.

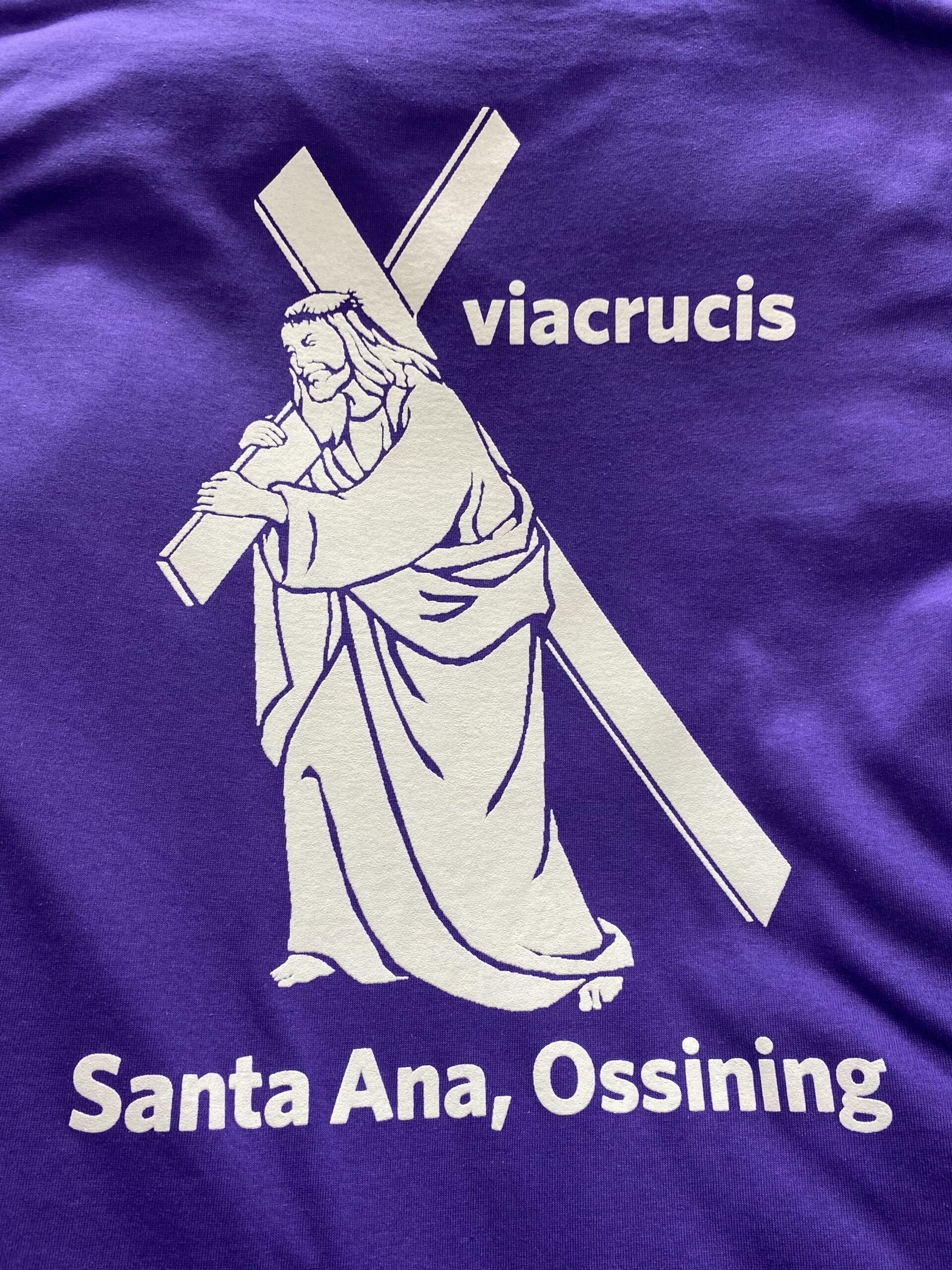

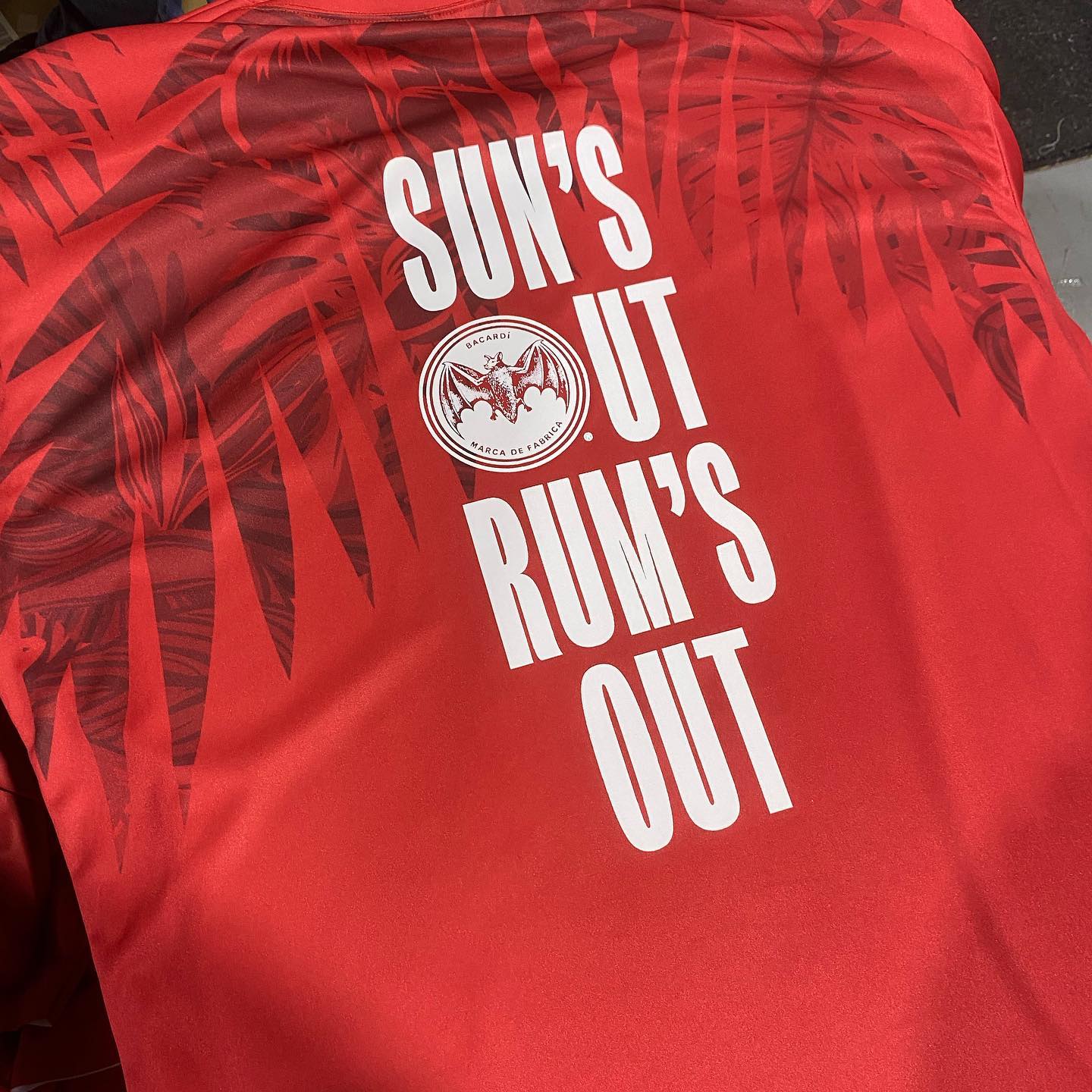

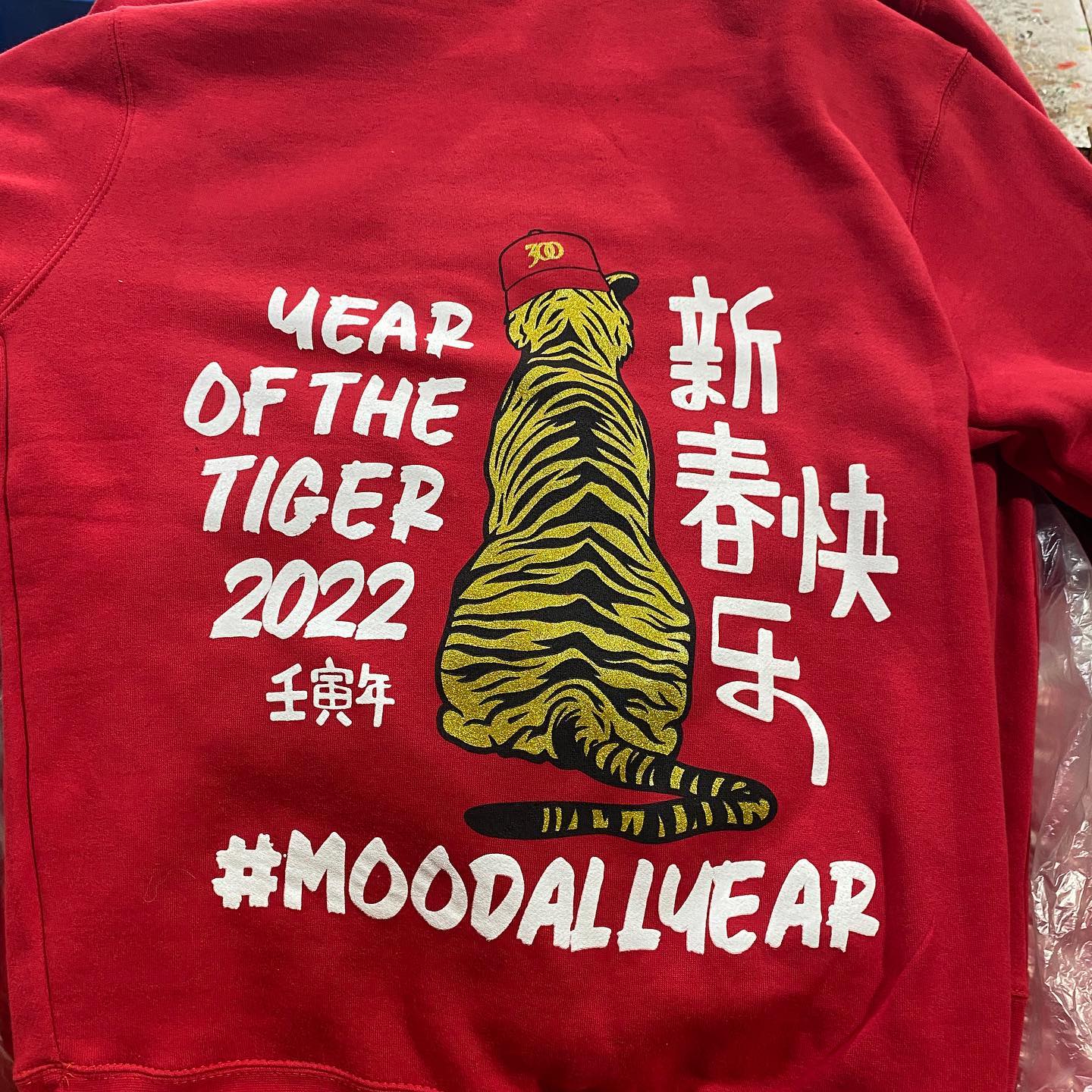

The ink is flexible, soft, and has excellent opacity on dark color garments. Not only are Fusion 180° ink prints bright, but the ink is also bleed and crack resistant.

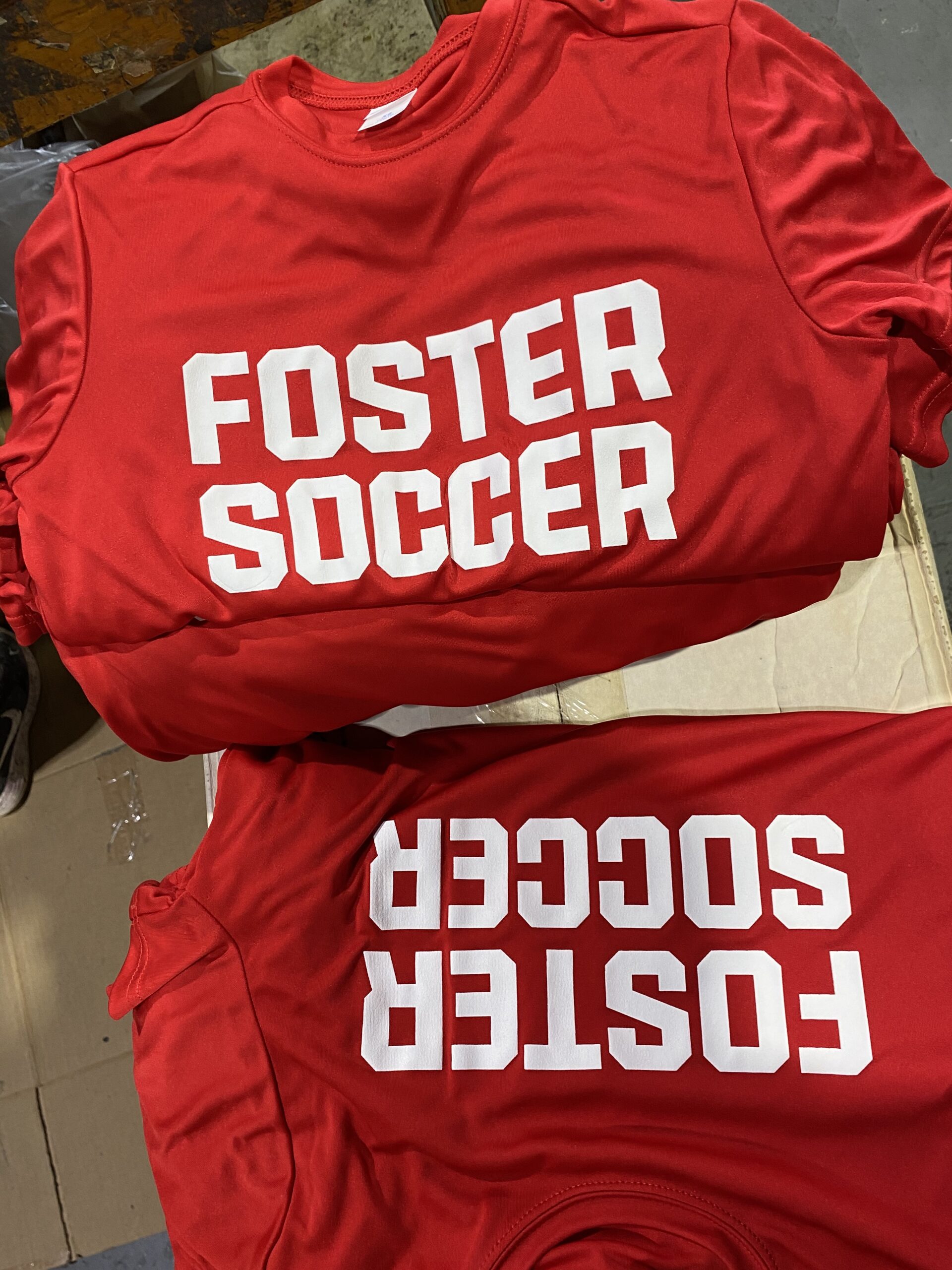

Our ink can print on virtually all fabrics including heat sensitive materials. A few fabrics that the ink can print on include polyester, soft vinyl, polypropylene, non-woven, artificial leather, nylon, 100% cotton, and 50/50.

100% polyester dyes tend to turn to gas when they are heated in the dryer causing plastisol ink dye migration problems. Our easy-to-use ink prevents dye migration on 50/50 sweatshirts, 100% polyester, and sublimated polyester due to the inks blocking capability and low cure temperature.

Fabrics will burn or shrink while flash curing in the conveyor dryer. The low flash temperature reduces the shrinkage of heat sensitive materials and makes it easier to hold registration while printing multi-color jobs. Low temperature ink is an excellent solution for all shrinking fabrics.

Quick Facts About Our White Ink:

1.Use an underlay screen of ink on dark color garments for best results

2. The height between the screen mesh and the substrate you are printing on should be 1/8 of an inch since white tends to be thicker

3. Less white ink is required to achieve good coverage on light color garments

4. The ink is Biodegradable

5. Excellent Opacity and Coverage

6. No Catalyst Needed

7. Works on All Fabrics

8. Cure with a Flash or at a Low Temperature

9. Covers Fibers on Cotton

10. Will not shrink or melt heat sensitive materials (nylon, non woven bags, polypropylene, etc.)

11. Adheres to thicker fabrics (50% cotton/ 50% polyester sweatshirts)

12. Prevents Dye Migration on 100% polyester, 50/50 sweatshirts, and sublimated polyester

13. Can be used as a transfer ink and foil adhesive

14. Prevents the elimination of toxic atoms from PVC Polymer and the formation of HCI (Hydro-Chloride Gas)

15. You may no longer need ink cleaners made with petro-chemicals such as blended solvents

16. Saves energy, consumption, and space

17. Reduces energy bill and emissions

18. Increases production

SAVE 15% off our next purchase at $85.00. Code: Take15

Also, we have FREE shipping at $200.00.

-

Fusion 180° White Ink$29.95 – $459.95

Fusion 180° White Ink$29.95 – $459.95 -

FUSION 180 INK- STOCK COLORS$29.95 – $459.95

FUSION 180 INK- STOCK COLORS$29.95 – $459.95 -

FUSION 180° BLACK INK$29.95 – $2,145.00

FUSION 180° BLACK INK$29.95 – $2,145.00 -

FUSION 180° FLUORESCENT INK$36.50 – $579.95

FUSION 180° FLUORESCENT INK$36.50 – $579.95 -

BIO-RE-705 reducer$18.00 – $59.00

BIO-RE-705 reducer$18.00 – $59.00 -

CFB100- Cotton White Ink$18.00 – $320.00

CFB100- Cotton White Ink$18.00 – $320.00 -

Inkjet Media Film$45.59 – $84.29

Inkjet Media Film$45.59 – $84.29 -

Blue Fusion 180 Stock Color Collection$29.95 – $459.95

Blue Fusion 180 Stock Color Collection$29.95 – $459.95 -

Multi-purpose Ink Cleaner IC-510$18.95 – $327.95

Multi-purpose Ink Cleaner IC-510$18.95 – $327.95