How to Screen Print with Low Temperature Glow-in-the-Dark Ink

Adding specialty inks to your screen print shop can help you stand out among the competition. Specifically, Glow-in-the-dark ink, will add an interesting, unique, and fun element to your shop! This type of ink is perfect for fire fighting, mining, and traffic safety gear, toys and novelties, t-shirts and uniforms. Our glow-in-the-dark ink is ‘ready to use’ and easy to work with if you follow our simple tips!

About:

Our phosphorescent ink is ready to use. The ink shows its brightness and luminosity from phosphors that we already have added into our formula. This chemical stores energy and radiates it out as a glow. Phosphors glow when the lights turn off. The phosphors are charged in ultra-violet light or bright sunlight for 20 to 30 minutes.

How to:

• We recommend using up to 200 mesh and curing at 260°F through the dryer for 40 seconds. LOW TEMPERATURE INK is perfect for glow in the dark specialty effects due to the fact that too much heat can interfere with the phosphorescence and dull the glow.

• Don’t forget that our glow in the dark ink does require thicker ink deposits!

• Use a screen that allows the coarse phosphorescent particles to pass through onto the substrate.

• Mix thoroughly before use. Our ‘Glow in the Dark’ ink is ready to use, however for the best results give the ink a good mixing before you print.

• Use a layer of white under base in order to achieve a really bright and beautiful glow-in-the-dark effect on any color garment that you are using. The ink can be used on both white, light, and dark color garments and will still glow!

• FUN FACT: We offer glow-in-the-dark ink in a variety of colors. We can create any color you would like by adding fluorescent ink to change the hue. However, the human eye is most sensitive to green light. This means that green glow appears brighter and is favored by screen printers. Our listing is ‘green’ glow in the dark ink, however if you do want another color please write this in the comment section at checkout.

Additional Tips

Successfully printing with our specialty inks comes down to testing and experience. Here are 6 Tips to get you started.

1. Start Small. A small amount of specialty ink incorporated can have a huge impact.

2. Artwork. Understand how the texture and detail will affect your artwork.

3. Ink Mixer. Purchase a formulator ink mixer to prepare your inks. Ex: Drill and Mixing Blade, Jiffy Paint Blade, or Agitate Impeller

4. Squeegee. When printing textiles use a medium hard (65-85 durometer) Squeegee.

5. Perform Trial Runs. Test prints are important, as practice makes perfect. A trial run is necessary to make sure that your specialty ink comes out on the print the way you intend.

6. Record your Results. Keep track of your specialty ink projects for future references.

If you are looking to stand out, receive cool and crisp screen prints with awesome effects that are bright and beautiful, give our glow in the dark specialty ink a try!

GLOW IN THE DARK

-

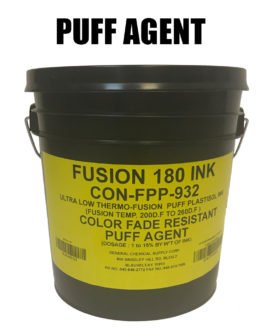

Low Cure Puff Agent$44.00 – $149.00

Low Cure Puff Agent$44.00 – $149.00 -

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

Glow in the Dark Fusion 180° Ink$68.00 – $249.00 -

FUSION 180° METALLIC INK$69.00 – $269.00

FUSION 180° METALLIC INK$69.00 – $269.00 -

FUSION 180° FLUORESCENT INK$36.50 – $579.95

FUSION 180° FLUORESCENT INK$36.50 – $579.95 -

FUSION 180° SHIMMER INK$49.95 – $719.95

FUSION 180° SHIMMER INK$49.95 – $719.95 -

FUSION 180° INK- PROCESS COLORS$22.95 – $462.95

FUSION 180° INK- PROCESS COLORS$22.95 – $462.95