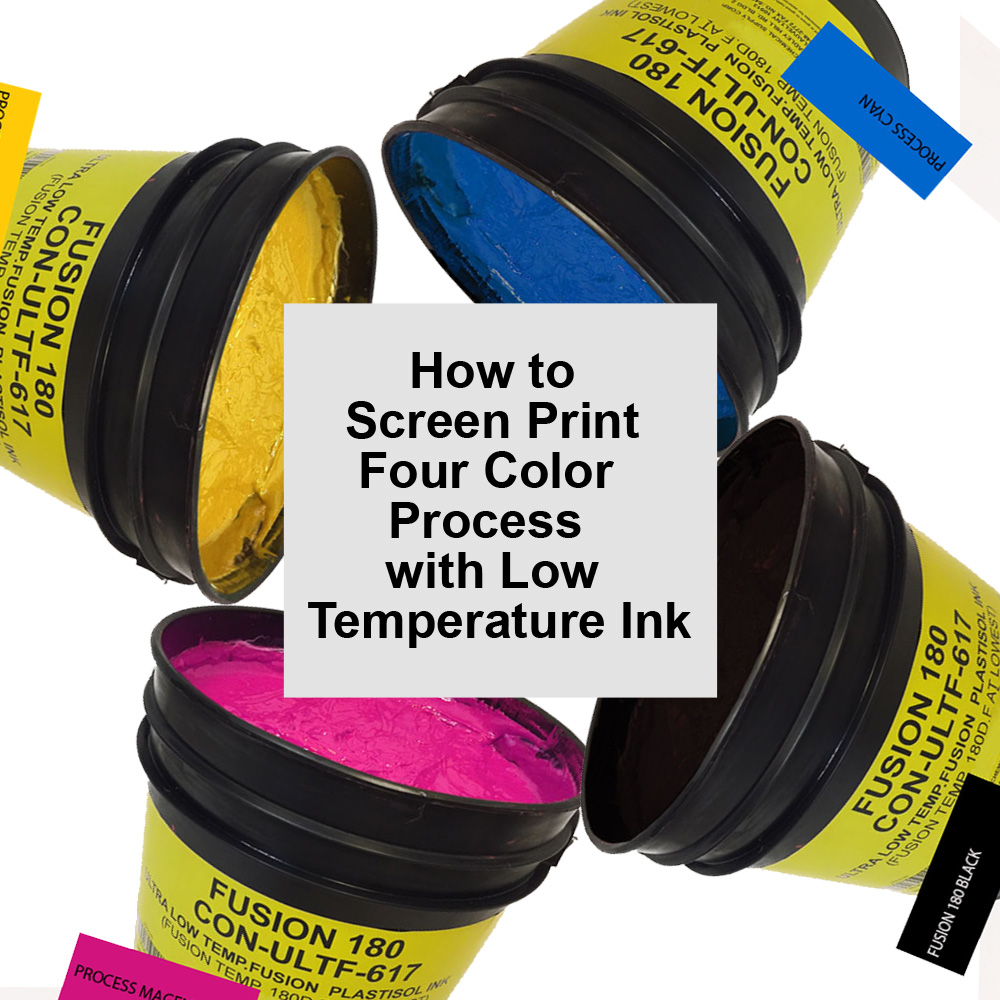

How to Screen Print Four Color Process with Low Temperature Ink

How to Screen Print Four Color Process with Low Temperature Ink

Four color process screen printing is a color separation system where the image is separated into cyan, magenta, yellow, and black. These four colors form a photo-realistic print reproducing the original color image. Screen printers are able to achieve this due to the fact that the four color halftone dots overlap and mix. The small dots are created to print different angles to create the final look. The artwork is generally developed digitally or with a software specifically for CMYK screen printing. Four color process is widely used in the screen printing industry, due to the fact that it is cost effective and is cheaper than toner based or digital printing. Surprise your customers with a beautiful photo-realistic print using the four color process system and our low temperature ink by following our simple tips!

Tip #1: Separate Artwork Carefully. Quality artwork is important regardless of the type of screen printing job that is at your hands, however with CMYK you need to pay extra attention in order to achieve a beautiful, crisp, and clear image on your substrate. As always, begin with a high resolution image. Adjust your settings specifically for CMYK screen printing.

Settings:

1. Screen Angles: 45% Yellow, 15% Cyan, 75% Magenta, 75% Black

2. Line Count: 26.6 Lines per Centimeter

3. Halftone Dots: 15% and 85% density

4. Adjust: Adjust halftone dot to an elliptical shape

5. CMYK has a limited color range. When a desired color is out of range add a spot pantone color and print it beneath the 4cp in the area that is out of range. A light ink deposit works best in this case. Use a 305 mesh for the spot color screen.

Tip #2: Select the Right Substrate. Select a substrate with a tight weave, as thicker materials can interfere with the detail of the halftone dots. White colored garments are recommended.

Tip #3: Set up Your Machine Properly. Setting up your machine the correct way will result in a crisp and clear image that is the correct colors and is not blurry.

Mesh: 305 Mesh Count

Screen: Densely Woven

Screen Tension: 25 Newtons/ Square Centimeter (Not less than 22 or more than 30)

Off-Contract Distance: 0.040 Inches

Squeegee: 70-75 durometer at a 15 degree angle

Tip #4: Learn How to Screen Print. As always, with low temperature ink, you have to cure the substrate at 260 degrees Fahrenheit for 70 seconds through the dryer. Specifically, with four color process, this involves wet-on-wet screen printing. This means that there is no flashing between colors. Use one print-stroke per color and don’t forget that you need to begin with the lightest color yellow to the darkest color black. If you are screen printing on a dark color garment and need to use an underlay, flash cure this layer first. Don’t forget to print from yellow to magenta to cyan to black!!!!!

Quality artwork, the right garment, and setting up your machine properly will award you with a beautiful and detailed screen print using our four color process inks. Don’t forget to cure at the low temperature!

View Our Four Color Process Ink Listing Here

-

FUSION 180° INK- PROCESS COLORS$22.95 – $462.95

FUSION 180° INK- PROCESS COLORS$22.95 – $462.95

1 thought on “How to Screen Print Four Color Process with Low Temperature Ink”

Comments are closed.

[…] The print above is CMYK print. Shop our process colors here! […]