Additional care is necessary when printing on sweatshirts, as they are not the easiest to screen print on. Avoiding seams, pockets, zippers, and hoods on the thicker, fleecier texture can be difficult. However, this guide will help you master printing designs on sweatshirts and provides the proper technique.

Additional care is necessary when printing on sweatshirts, as they are not the easiest to screen print on. Avoiding seams, pockets, zippers, and hoods on the thicker, fleecier texture can be difficult. However, this guide will help you master printing designs on sweatshirts and provides the proper technique.

-

Artwork

Adjust your artwork so that the design and size do not interfere with the seam, pocket, or zipper. You might need to shrink the artwork in order to print on the back of a hoodie, front of a quarter zip, between a collar, or inside a pocket.

-

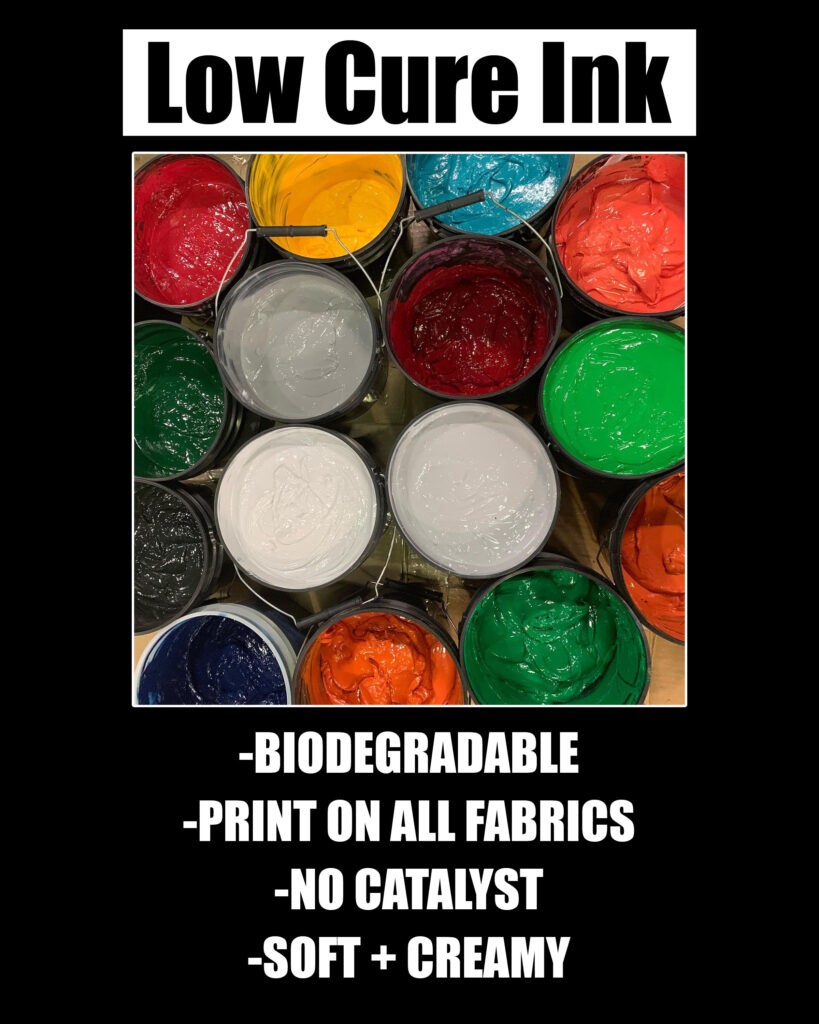

Proper Ink

Most sweatshirts are synthetic blends. 100-percent synthetic sweatshirts shrink when exposed to a high amount of heat. Fusion 180° is a biodegradable ink that is made for screen printing on Sweatshirts and heat sensitive materials. Curing Fusion 180° ink at 260° will prevent the material from shrinking, block dye migration, and protect the integrity of the fabric with excellent coverage. The low temperature will also cover fibers.

-

Increasing the Off Contact

Since you are working with a thicker substrate, you need to increase your off-contact distance to ¼ of an inch. This will enable you to have enough room for your screen to snap cleanly off the sweatshirt, which creates a clean and crisp print. The rule is to double the off-contact distance.

-

Flashing Between Two Colors

Our ink will not sit on the surface and will adhere to the thicker material of sweatshirts. You won’t need as many flashes with our ink. It is recommended that you flash between two to three colors when printing on sweatshirts.

-

Cure at a Low Temperature

You have to cure our ink at a low temperature to prevent dye migration. Dye migration is an issue with synthetic sweatshirts. The dye could bleed out of your substrate and alter your ink color. This occurs when the synthetic sweatshirt overheats. Once again, lowering the temperature of your dryer comes to the rescue and will prevent dyes from migrating. If dye migration is not a concern, you will still have to lower the temperature of your dryer in order to ensure that the ink will adhere to the sweatshirt, as the sweatshirt tends to be a thicker substrate.

Sweatshirts are important to any screen print shop and achieving a crisp and clear print on a hoodie or sweatshirt is relatively simple once you make the necessary adjustments. Learn how to print on Nylon by reading our next blog post.

-

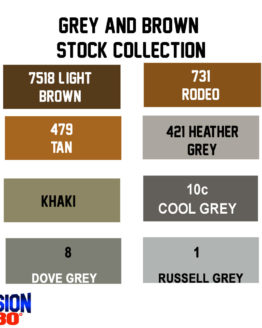

Grey and Brown Stock Collection$29.95 – $459.95

Grey and Brown Stock Collection$29.95 – $459.95 -

Purple and Pink Stock Color Collection$29.95 – $459.95

Purple and Pink Stock Color Collection$29.95 – $459.95 -

Blue Fusion 180 Stock Color Collection$29.95 – $459.95

Blue Fusion 180 Stock Color Collection$29.95 – $459.95 -

Green Fusion 180 Stock Color Collection$29.95 – $459.95

Green Fusion 180 Stock Color Collection$29.95 – $459.95 -

Yellow Fusion 180 Stock Color Collection$29.95 – $459.50

Yellow Fusion 180 Stock Color Collection$29.95 – $459.50 -

Orange Fusion 180 Ink Stock Color Collection$29.95 – $459.95

Orange Fusion 180 Ink Stock Color Collection$29.95 – $459.95 -

Red Fusion 180°Ink Stock Collection$29.95 – $459.95

Red Fusion 180°Ink Stock Collection$29.95 – $459.95 -

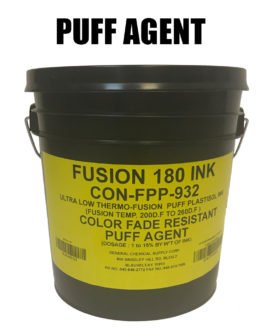

Low Cure Puff Agent$44.00 – $149.00

Low Cure Puff Agent$44.00 – $149.00 -

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

Glow in the Dark Fusion 180° Ink$68.00 – $249.00

1 thought on “5-Step Guide for Printing on Sweatshirts”

Comments are closed.

Great guide. Thanks for sharing.

Bruce, https://www.printavo.com