Fusion 180° is the ink of the future. Our dream was to create a extreme low temperature ink that will change screen printing for everyone in the industry and that is exactly what we accomplished with dedication and determination. Do you run into problems when printing on heat sensitive materials? Do you want to save money by not having to replace garments damaged by high heat or dye-migration? Look no further… Fusion 180° was created to solve all of these issues. All you have to do is lower the temperature of your dryer.

Fusion 180° is the ink of the future. Our dream was to create a extreme low temperature ink that will change screen printing for everyone in the industry and that is exactly what we accomplished with dedication and determination. Do you run into problems when printing on heat sensitive materials? Do you want to save money by not having to replace garments damaged by high heat or dye-migration? Look no further… Fusion 180° was created to solve all of these issues. All you have to do is lower the temperature of your dryer.

LISTED ARE 16 FACTS ABOUT FUSION 180° INK:

- Proper mesh and curing temperature depends on the thickness of ink deposit, garment, color of garment, artwork, and desired effect

- The ink cures at 240°F to 260°F for 70 seconds or at 450° with a flash

- The mesh range is 86 mesh/inch to 305 mesh/inch

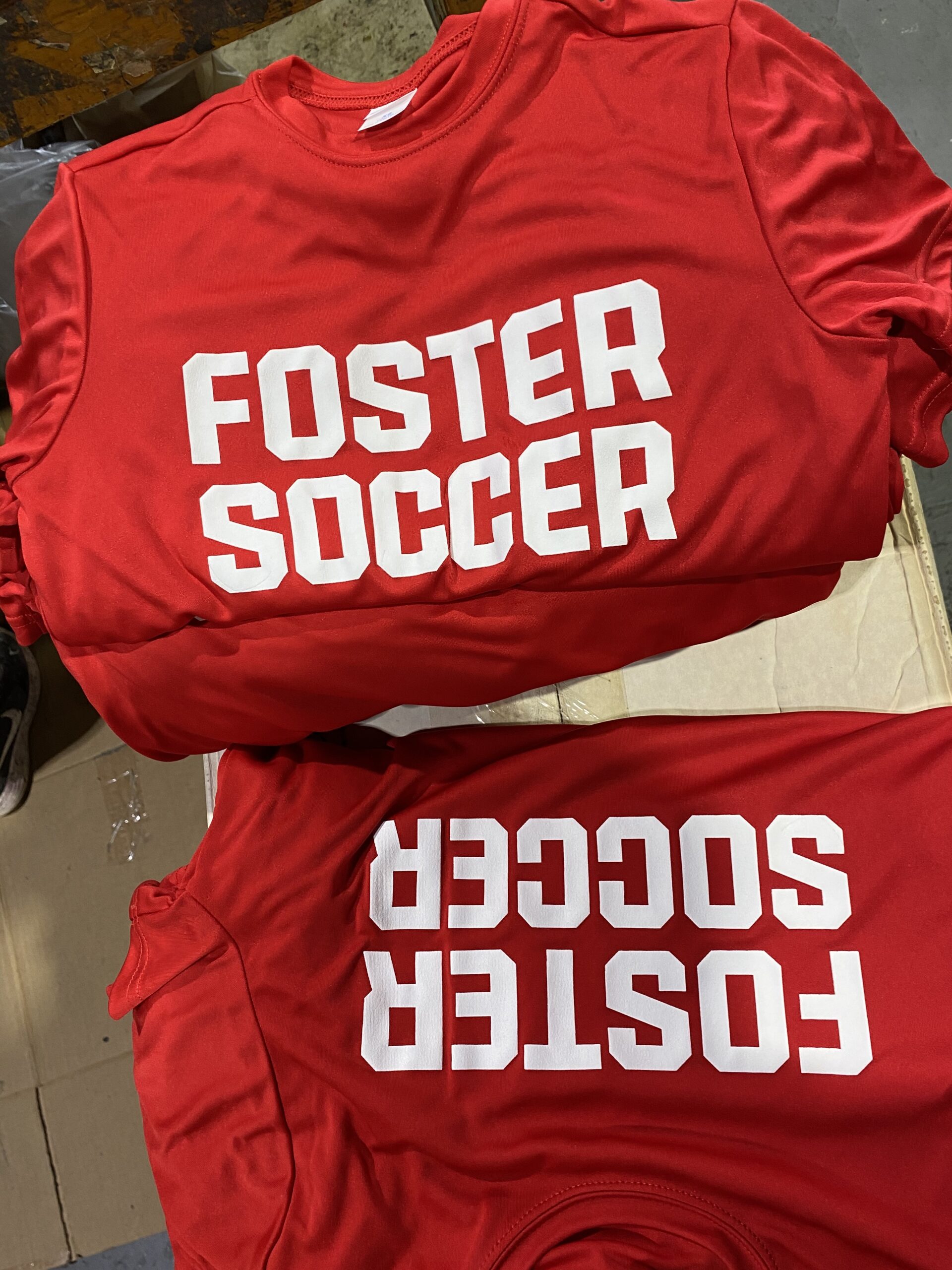

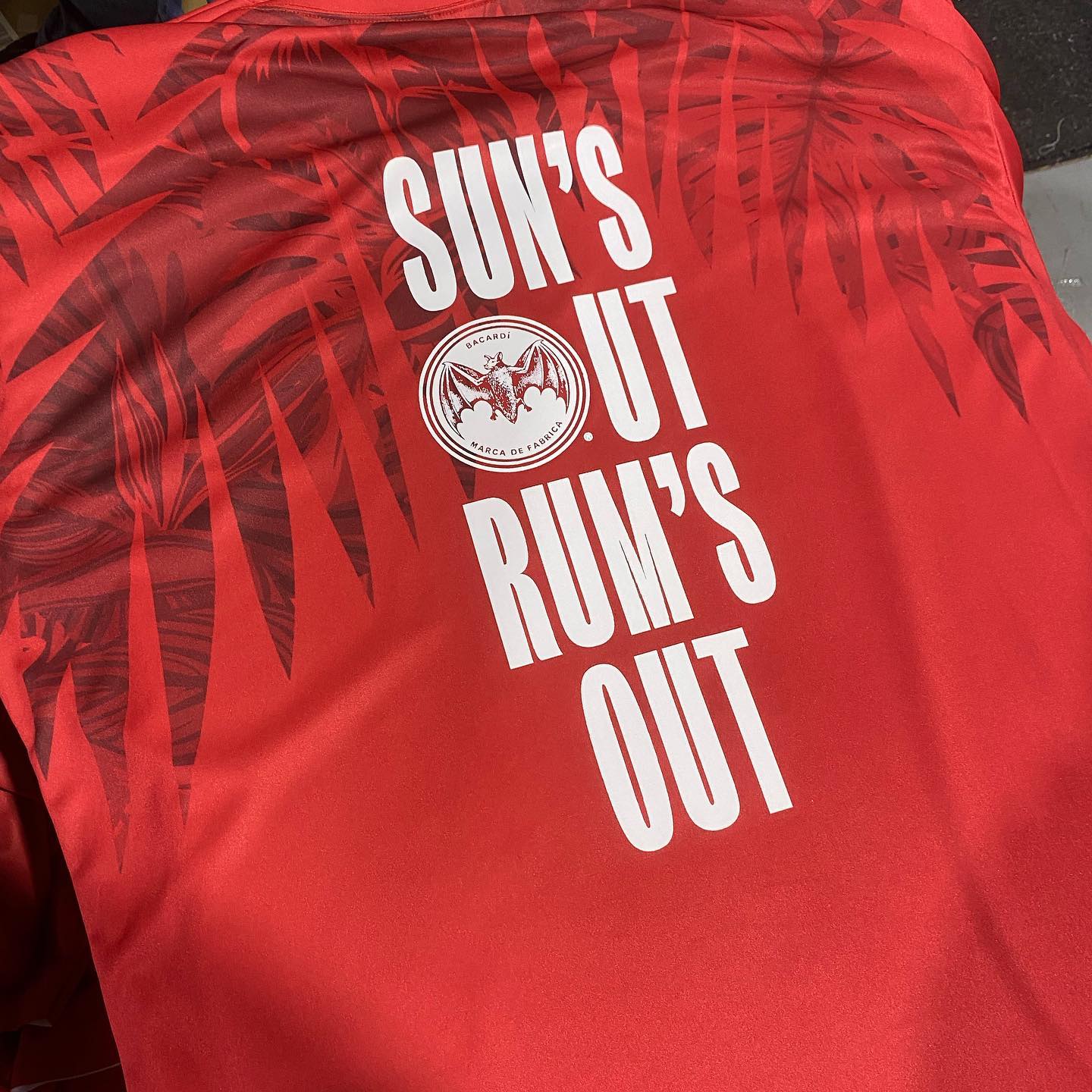

- Flexible, soft, and has excellent opacity on dark color garments

- Bleed and crack resistant

- No catalyst needed

- Will not shrink or melt heat sensitive materials (nylon, non woven bags, polypropylene, etc.)

- Adheres to thicker fabrics (50% cotton/ 50% polyester sweatshirts)

- Covers fibers on 100% cotton

- Prevents Dye Migration on 100% polyester, 50/50 sweatshirts, and sublimated polyester

- Can be used as a transfer ink and foil adhesive

- Prevents the elimination of toxic atoms from PVC Polymer and the formation of HCI (Hydro-Chloride Gas)

- You may no longer need ink cleaners made with petro-chemicals such as blended solvents

- Saves energy, consumption, and space

- Reduces energy bill and emissions

- Increases production

3 Tips for Screen Printing with Low Cure White Ink

3 Tips for Screen Printing with Low Cure White Ink

- Use an underlay screen of ink on dark color garments for best results

- The height between the screen mesh and the substrate you are printing on should be 1/8 of an inch since white tends to be thicker

- Less white ink is required to achieve good coverage on light color garments